Butt Shear and Shear Blade

Used to clean the remaining scrap from the die, the shear blade should be changed periodically because it is the most deformed part.

Used to clean the remaining scrap from the die, the shear blade should be changed periodically because it is the most deformed part.

In order to save time while a cassette is used on the press, a second cassette is on a stand is used to mold changing.

Bolster: the place were molds are positioned; used to help loading the mold into the cassette

Loads the billets on the hot cutting machine in the desired size.

Our research shows that workers have a lot of difficulties in mold separation processes, in order to ensure the safety of workers and a faster results we have developed a full automatic mold separation machine.

Express Mühendislik is capable of manufacturing all lines of extrusion press machine like

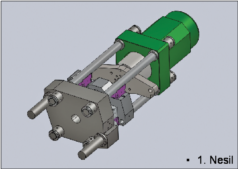

1. Double effect piston designed extrusion systems

2. Floating piston designed extrusion systems

3. Tandım piston designed extrusion systems

In addition we have developed a forth version which is an improvement of the Tandem piston system and driven by a servo motor. Our new model is approved and under manufacturing process with the support of TÜBİTAK (The Scientific and Technological Research Council of Turkey).

TANDEM PISTON SYSTEM with SERVO MOTOR TECHNICAL DETAILS

– “4 inch Billet

– Prestressed

– Servo Motor Driven

– 600 UST Metal Extrusion Press

SPECIFICATION:

– 75% total energy saving (A+++)

– Faster Production

– Less dead (idle) time

– More powerful in a smaller place

– Less hydraulic components

– Silent Working